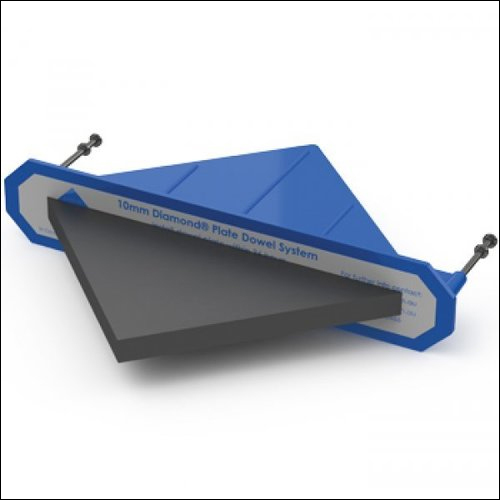

Diamond Dowel

MOQ : 100 Units

Diamond Dowel Specification

- Application

- Concrete Floor

- Product Type

- Diamond dowel

- Main Material

- ABS & MS Plate

- Surface Treatment

- Floor Stabilizer

- Size

- 8" X 6"

- Weight

- 600 Grams (g)

- Usage

- Transfer of load

- Feature

- No breakage

Diamond Dowel Trade Information

- Minimum Order Quantity

- 100 Units

- Supply Ability

- Unit

- Delivery Time

- Days

- Sample Available

- Yes

- Sample Policy

- Free samples are available

- Main Domestic Market

- All India

- Certifications

- If required

About Diamond Dowel

A diamond dowel is a type of load transfer device used in concrete construction to connect adjacent concrete slabs. It consists of two diamond-shaped steel plates with strategically placed dowel pins. Diamond dowels are designed to allow controlled movement between the slabs while efficiently transferring loads, reducing joint stress, and preventing cracking in concrete pavements and floors.

Frequently Asked Questions (FAQ):

Q: What is a diamond dowel?

A: diamond dowel is a load transfer device used in concrete construction to connect adjacent concrete slabs. It typically consists of two diamond-shaped steel plates with dowel pins, designed to provide load transfer and accommodate movement at construction joints.

Q: How does a diamond dowel work?

A: When concrete slabs expand and contract due to temperature changes or load-bearing, a diamond dowel allows for controlled movement between the slabs. The dowel pins within the diamond shape permit axial, lateral, and rotational movement, reducing stress on the joint and preventing cracking.

Q: What are the benefits of using diamond dowels in concrete construction?

A: Diamond dowels offer several advantages, including improved load transfer efficiency, reduced joint stress, prevention of joint faulting and spalling, increased durability, and enhanced long-term performance of concrete pavements and floors.

Q: In which applications are diamond dowels commonly used?

A: Diamond dowels are commonly used in various concrete construction projects, such as highways, airport runways, industrial floors, commercial warehouses, and other areas where load transfer and joint movement control are critical.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry